Wood Track Drawer Guide Plans

Wooden drawer slides

This article besides available in SpanishWhenever I build something with drawers, never buy metal drawer slides, simply make the drawer slides as an integral part of the drawer, and out of wood. Information technology just wouldn't be right to use metallic drawer slides, and for many of the things I build, metallic drawer slides would not even be suitable. Metallic drawer slides are often non very stiff, expensive, and likewise make it harder to take the drawer out of the cabinet.

This article summarizes different drawer designs I have, and my experiences with these types of drawers. I'grand hoping this volition assistance you decide which styles of drawers to make when you exercise brand some.

Hardwood drawer slot rails on hardwood rail

The best sliding and most durable drawer slides are of course if you accept hardwood sliding on hardwood. Preferably with a very dense and close-grained hardwood such as maple.My dad often makes drawers like that on furniture he builds.

I have personally never used this approach though - I don't have my own source of hardwood, and its too expensive to buy simply to make drawers.

Hardwood drawer track in hardwood channel

To economize on the use of hardwood, I have often made the drawers with a hardwood rail sticking out the side, and made that slide in a hardwood channel in the piece of furniture. I used this approach for a drawer in a TV table. With the drawer only filling part of the space underneath the table, the aqueduct simply spanned from the front to the back for the drawers to slide in.

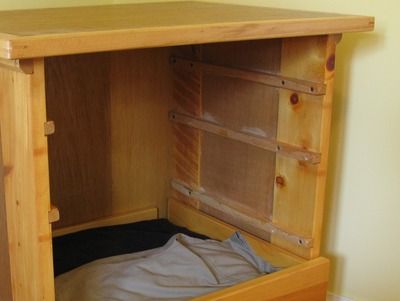

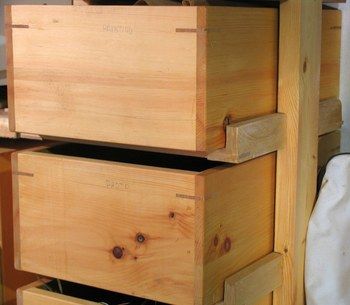

I also used this approach in a drawer breast, shown at left. The drawers get right to the edge of the cabinet, then it was more expedient and space efficient to just attach pieces of hardwood to the within sides of the cabinet. I only used pieces of scrap hardwood I had lying around, which is why the pieces of wood take odd shapes to them

I also used this approach in a drawer breast, shown at left. The drawers get right to the edge of the cabinet, then it was more expedient and space efficient to just attach pieces of hardwood to the within sides of the cabinet. I only used pieces of scrap hardwood I had lying around, which is why the pieces of wood take odd shapes to them

Each drawer has a bottom guide, and a top guide. The tiptop guide is at that place to keep the back of the drawer from tipping out if its pulled out more than half way and permit go.

A refinement was to make the peak rail a petty bit shorter on the forepart. That way, if the drawer is most out, rather than take a crazy amount of leverage on the rails and potentially damage things, it will simply autumn out. Information technology also makes the drawer easier to insert back in the chiffonier if information technology was taken out, as the dorsum of it just needs to be placed on the lesser rails, and pushed in, rather than aligning it precisely get-go.

I originally made this drawer chest to slide under a workbench in the basement. But as a overnice touch, I spent $20 for quarter inch thick pieces of oak that I glued to the forepart of the drawer. The whole thing concluded up looking so overnice, it'due south now nether a desk in my new identify.

Hardwood rail on bottom of drawer

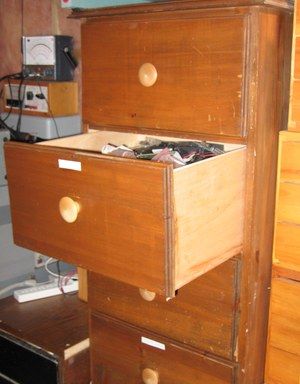

A variation of this is to put the slides towards the lesser. I did this with another box of drawers, which for a while, served as desk drawers, as seen at left.

A variation of this is to put the slides towards the lesser. I did this with another box of drawers, which for a while, served as desk drawers, as seen at left.

For these drawers, I made the slides higher, only narrower. With the extra width of the hardwood slides, gluing them but to the sides of the drawer was quite sufficient.

The slides actually are the bottommost part of the drawer, and to some extent aid hold the lesser in place. Being fairly narrow, they as well make this drawer case more space efficient. They practise wait slightly odd out of the cabinet though, simply overall, information technology'south a very practical combination.

I used odd shaped pieces of scrap wood for the guide rails inside the cabinet, hence the odd shapes in the image above right.

I had built that drawer cabinet for the basement originally. The plywood example was reclaimed plywood. On a whim, I put $.25 of oak on the drawer fronts, and the whole thing ended upwards looking as well skillful for the basement. I combined it with a table to course a 'desk' - see shot earlier. The tabular array office also makes a decent dining table if the tabletop is not mounted off centre. Its like a furniture wardrobe remix!

Softwood drawer slot on hardwood track

For lighter drawers, I have oft used hardwood just for the rails. This doesn't slide quite every bit well as hardwood on hardwood, only it has done ok then far, and is easier to build and very much economizes on the expensive hardwood.I used this approach for my detach-able desk drawers. With the drawers sliding on maple runway, I left the whole drawer section open, with the rails that the drawers slide together actually property the drawer frame together. With the whole drawer frame being disassemble-able, this worked out well, both mechanically and visually.

I over again used the softwood drawer slot on a hardwood slide method for my disassemble-able dressers. Once again, non needing much of a frame around the drawers worked to my advantage, every bit I was able to keep the rest of the dresser to a blank minimum.

Other than not existence as durable, and not sliding besides, the risky role of this pattern is that it might consequence in the drawer getting divide apart if its mostly pulled out, and then pushed down on hard. With the rail in the end of the slot, it will put a lot of force on the drawer sides, forcing the pinnacle and lesser apart. The middle is weakened already considering it has the slot cut in it. I always brand sure the sides are very deeply glued to the back, and so that the dorsum, which has no slot in it, would have to be dissever apart as well for this to happen.

It's probably a paranoid fear though, because I have never had any of my drawers fail that manner, but then once again, I don't abuse them.

The drawers splitting apart is not much of a concern for smaller drawers though. Dorsum when I was in high schoolhouse, I made a lot of wooden drawer boxes to sort all of my electronic and mechanical parts into. The simplicity of this design worked out well, and I never worried almost the drawers getting damaged.

The track that the drawers slide on are only glued to the cases for the forepart one-half. That way, the boards of the case, which change in width with humidity, will exert less force on them.

I don't recollect I'd take the time to make then many drawers again (the shots above show just some of them), but when I was withal in loftier school, I had trivial money and lots of time. And the wooden drawers do concur up to time better than plastic ones would.

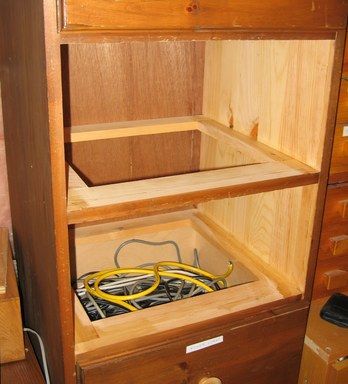

Softwood on softwood

The worst kind of wooden drawer slide is softwood on softwood. This may work reasonably well for light drawers, simply for heavy drawers, or drawers that get used much, it's a large no no. Soft on soft just doesn't slide overly well, and wears out quickly. It gets even worse if information technology has to slide on something cross grained. Its this kind of drawer slide that gives wooden drawer slides a bad proper name.For this reason, I have never congenital anything where I had softwood glide on softwood. I practice take one instance of such a slice of furniture in my basement though. A boarder left it behind many years ago. Its a fairly space efficient storage unit of measurement though, which is why I even took it with me when I moved to my new identify.

The drawer sides are made of plywood, so partially, the drawers slide on the finish grain to some extent, which would cause additional wear to the cabinet if they were used frequently.

I was able to make the drawers slide more than hands though by putting some adequately slippery floor varnish on the chiffonier where the drawers slide on, and on the bottom of the drawers. Varnish on the runway doesn't ever help make them slide ameliorate - it very much depends on what kind of varnish you utilize.

Centre guide rail

A lot of older wooden dressers have a eye guide rail, often fabricated out of forest, with a wood or metal C channel sliding on it. The metal C aqueduct is not applied for dwelling house built article of furniture, although one can make wooden ones. My dad built using a similar approach.This approach is useful when the piece of furniture uses a face frame, as its makes it easy to add the single centre rail that the drawer slides on. It as well helps reinforce the drawer lesser, so thinner fabric can exist used for that.

It does unfortunately use up a lot of vertical space, as at that place needs to exist a piece of woods to become between the drawers, and the drawers demand to have room on the bottom for the rails. The pictures are from a piece of piece of furniture fabricated by my dad. Because I ever want to optimize the corporeality of space inside the drawers, I have never used this technique myself.

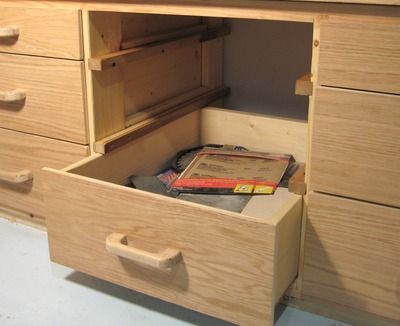

No guide track

A very space efficient manner to brand drawers is to make with no slot or guide rail at all, and merely have the box slide between track on the side. I used this approach for my Workbench drawers  The advantage of this approach is that you don't need whatsoever extra space on the side for the guide rails. The vertical space used past the guiderails is even so usabble for storage because the drawer below can be piled higher to utilize that infinite, so long as the drawer front end is likewise every bit high. Otherwise, the contents would scrape against the drawer front of the drawer above when the drawer is opened.

The advantage of this approach is that you don't need whatsoever extra space on the side for the guide rails. The vertical space used past the guiderails is even so usabble for storage because the drawer below can be piled higher to utilize that infinite, so long as the drawer front end is likewise every bit high. Otherwise, the contents would scrape against the drawer front of the drawer above when the drawer is opened.

The disadvantages of this arroyo is that ane needs to exit enough clearance above and beneath the drawers to allow expansion due to humidity changes, especially if ane builds the drawers in the wintertime when the air is drier.

The other take hold of is that is tricky to make the drawer slide on hardwood. For these drawers, I ended up gluing a strip of hardwood to the bottom edges to make for a hardwood on hardwood slide for these drawers.

A lot of old wooden desks from the 60's and lxx's apply this approach. They made the front, back and sides all out of hardwood for these, so the drawers already ended up sliding hardwood on hardwood. The drawer bottoms would are mounted in a rabbet in the sides, and then that the bottom-most function of the drawer is really the sides.

I didn't worry also much near how well these drawers on this storage unit would slide though. They are drawers in a way, but in another style, just boxes on a rack. I thought I'd include it because I think it's a groovy variation on the storage drawer idea.

I didn't worry also much near how well these drawers on this storage unit would slide though. They are drawers in a way, but in another style, just boxes on a rack. I thought I'd include it because I think it's a groovy variation on the storage drawer idea.

Making drawers slide easily

One of the keys to making adept wooden drawers is to make the drawers slide easily. The most constructive thing to do is to brand sure that the drawers slide on hardwood. The next step is to treat the surface to brand information technology glide more than easily. Oil

Putting any sort of oil on the slides makes them slide superbly. Unfortunately, this is non always a good idea, particularly if the drawer doesn't accept a slot or rails on the side. Just imagine putting your sock drawer downwardly on the bed! The other reason not to use oil though is that oil eventually becomes viscous, as the thinner components of the oil will very slowly evaporate - even at room temperature. So unless you have some wooden slide that is part of some sort of wooden machine that you await to re-lubricate, avoid oil.

Wax

A less effective, but much cleaner method is to use wax. Just rubbing a candle onto the rails makes a big departure. For added effectiveness, estrus the parts upwardly a picayune with a heat gun before awarding. The upshot is rather long lasting, but even if it does article of clothing off somewhen, at least it never gets sticky like oil does.

Varnish

Some types of varnish can help a drawer slide more than freely, just not all varnishes. So experiment first. I take had good results with this varnish, but your results may vary. I suspect for heavy drawers, information technology wears away too quickly, but it seems to piece of work very well for lighter drawers.

If you practice use varnish, give the varnish an extra day to harden even afterward it is dry to the affect, so that you don't wear it off right away. Youy tin can besides add wax and/or a bit of oil to help information technology glide.

Gliding button

Gliding button

Another clever affair I see on commercial wooden drawers from the 60'south and seventy'south is some sort of metal or plastic button on the corner of the forepart that the drawer slides on. But that sort of push needs to exist totally smooth for it to be benign, and I oasis't plant a skilful source of a button like that. I don't think plastic covered thumbtacks would be near durable plenty, and metal ones would be likewise crude. So I haven't experimented with this method, though they work well on some old article of furniture I accept.

UHMW tape

UHMW tape, likewise known as "Ultra High Molecular Weight tape is a relatively new solution to the sliding problem. Its a relatively thick and tough sticky record, meant to exist practical to surfaces that need to slide.

For drawers that run really rough, such equally soft wood on soft wood, it can provide quick and significant improvement in how drawers slide. But I establish that it doesn't glide as easily every bit a smooth hardwood on hardwood that's been waxed. Also, information technology doesn't necessarily last very long, particularly if applied to a surface that isn't completely flat. And if it comes off, the sticky adhesive residue is a problem.

Related pages

Edifice Drawers for a mobile tool stand.

Edifice Drawers for a mobile tool stand.

Drawers for a storage cabinet

Drawers for a storage cabinet

harrisitardarand1976.blogspot.com

Source: https://www.woodgears.ca/drawers/index.html

0 Response to "Wood Track Drawer Guide Plans"

Post a Comment